Plastic Chrome Plating Machine/Chrome Coating Machine/Plastic Chrome Plating Equipment

Basic Info

Model No.: ZZ for Plastic chrome plating machine

Product Description

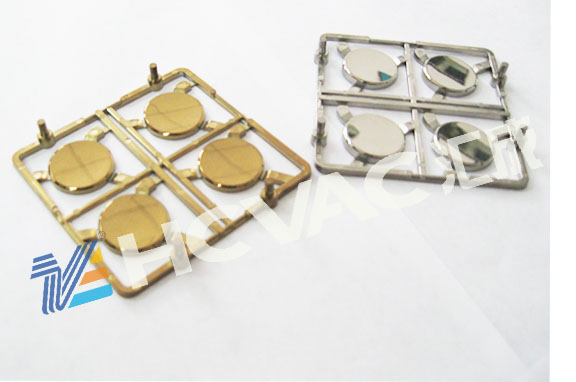

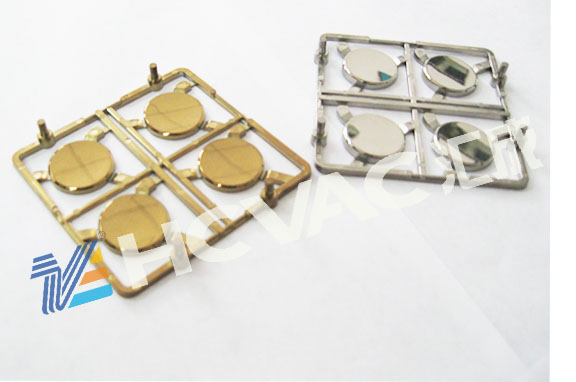

Model NO.: ZZ for Plastic chrome plating machine Coating: Vacuum Coating Certification: CE, ISO, SGS Name: Plastic Chrome Plating Machine Control Mode: PLC Touch Screen Automatic Control Structure: Vertical Single Door Coating Color: Silver, Golden, Red, Green, Blue, Rainbow Color Application: Cosmetic Caps, Shoe Heel, Acrylic Glass etc. Trademark: HCVAC Specification: CE, SGS, TUV HS Code: 85433000 Type: Plastic Chrome Plating Machine Substrate: Plastic Chrome Plating Machine Condition: New Coating Technology: Thermal Evaporation Coating Chamber Size: 1600*1800mm, 1800*2000mm Coating Film: Aluminum, Chrome, Nickle etc. Coating Material: ABS, PP, Acrylic Plastic Products, Glass, Ceramic Brand: Hcvac, Dongguan, China Transport Package: 20ft or 40ft Container Origin: Guangdong, China

Plastic chrome plating machine/chrome Coating Machine/Plastic chrome plating equipment

Is a high-tech environmentally friendly products for a variety of metal surface coating. For example: The watch industry (strap, case, dial, etc. ), hardware industry (sanitary ware, , door handles, door knobs, locks, etc. ), the architecture industry (stainless steel plate, stair railings, columns, etc. ), precision mold industry (standard mold, etc. ), the tool industry (drill bits, carbide cutters, broaches, shaving heads), the automotive industry (car wheels, car parts, piston, piston rings, etc. ), as well as pens, glasses, etc., to the surface both beautiful and wear functional wear layer. The main coated film: Ions of gold, silver ion, titanium nitride film, titanium carbide film, zirconium nitride film, titanium aluminum film, chromium nitride, and RP-plated and other superhard functional metal film, the workpiece coated by ion coating machine can improved hardness, wear resistance, anti-corrosion and more beautiful.

Characteristics:

1. The equipment uses the vacuum magnetron sputtering technique, twin cathode, MF sputtering technique, and matching with advanced control systems.

2. The production process all automated, continuous. The highest temperature of the plating workpiece is up to 350 centi-degree, the temperature is zone control and adjustable.

3. The vacuum chamber materials adopts SUS304, polishing inner vacuum chamber wall, spraying beads external vacuum chamber wall after polishing.

Applied industries: Surface vacuum coating for watch&clock, jewelries, tools, plastic, stainless steel sheet etc.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the part's history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

We will make the special coating solution for each customer; Combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Contact: Lillian Yang

Mobile: 0086-13825720037

Please send us your detailed requirements. We will provide the best solution for you!

Technical parameter:

Contact us if you need more details on Plastic Chrome Plating Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Chrome Plating Equipment、Plastic Chrome Coating Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Plastic chrome plating machine/chrome Coating Machine/Plastic chrome plating equipment

Is a high-tech environmentally friendly products for a variety of metal surface coating. For example: The watch industry (strap, case, dial, etc. ), hardware industry (sanitary ware, , door handles, door knobs, locks, etc. ), the architecture industry (stainless steel plate, stair railings, columns, etc. ), precision mold industry (standard mold, etc. ), the tool industry (drill bits, carbide cutters, broaches, shaving heads), the automotive industry (car wheels, car parts, piston, piston rings, etc. ), as well as pens, glasses, etc., to the surface both beautiful and wear functional wear layer. The main coated film: Ions of gold, silver ion, titanium nitride film, titanium carbide film, zirconium nitride film, titanium aluminum film, chromium nitride, and RP-plated and other superhard functional metal film, the workpiece coated by ion coating machine can improved hardness, wear resistance, anti-corrosion and more beautiful.

Characteristics:

1. The equipment uses the vacuum magnetron sputtering technique, twin cathode, MF sputtering technique, and matching with advanced control systems.

2. The production process all automated, continuous. The highest temperature of the plating workpiece is up to 350 centi-degree, the temperature is zone control and adjustable.

3. The vacuum chamber materials adopts SUS304, polishing inner vacuum chamber wall, spraying beads external vacuum chamber wall after polishing.

Applied industries: Surface vacuum coating for watch&clock, jewelries, tools, plastic, stainless steel sheet etc.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the part's history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

We will make the special coating solution for each customer; Combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Contact: Lillian Yang

Mobile: 0086-13825720037

Please send us your detailed requirements. We will provide the best solution for you!

Technical parameter:

| Mode Dimension | LH-800 | LH-1100 | LH-1250 | LH-1600 | LH-1800 |

| 800*1000mm | 1100*1000mm | 1250*1500mm | 1600*1800mm | 1800*1800mm | |

| Maily application | Metal decorative coating and Ceramic decorative coating | ||||

| Coating mode and main confirguration | Eight multi-arc targets | Ten multi-arc targets | Twelve multi-arc targets | Twenty multi-arc targets | Twenty two multi-arc targets |

| Power source | Electric-arc power, Filament power, | ||||

| Process gas control | Mass flowmeter + Electromagnetic ceramic valve | ||||

| Vacuum chamber structure | Vertical side opening door, pump system postposition, double water cooling | ||||

| Vacuum system | Molecule pump +Roots pump +Mechanical pump(8.0*10 -5 Pa) Diffusion pump +Roots pump +Mechanical pump(8.0*10 -4 Pa) | ||||

| Workpiece baking temperature | Normal temperature to 350 centi-degree PID control, radiation heating. | ||||

| Workpiece motion mode | Public rotation Frequency control: 0-20 rotation per minute | ||||

| Measure mode | Number display composite vacuum gauge: from atmosphere to 1.0*10 -5 Pa | ||||

| Control mode | Manual/Automatic/PC/PLC + HMI/PC four choice of control mode | ||||

| Remark | We can design the dimension of the equipment according to customer's special technique requirement. | ||||

Product Categories : Evaporation&Magnetron Sputtering Coating Machine

Other Products

Hot Products

Electrophoretic Paint2016 New Selling Cable Lugs Terminal Ends & ConnectorsHigh Quality Powder Drying/Curing Oven with Various Heating EnergyElectrostatic Powder Coating Equipment for AluminumProfessional Manufacturer Autophoresis Coating Line for SuspensionPaint Manufacturing EquipmentMetal Surface Pretreatment Device (DIP tank type)Aluminium Powder Coating & Electrophoretic Painting LineHigh Quality Electric Control SystemProfessional Electrostatic Spraying/ Painting MachineBest Quality Electrophoresis Coating Line for CarComplete Stainless Steel Plate Powder Coating LineAirless Paint Sprayer, Paint GunAutomatic/ Manual Paint Spraying/ Powder Coating MachineIndustrial Automatic Conveyor MachinesManual/ Automatic Powder Coating Machine for Metal Products